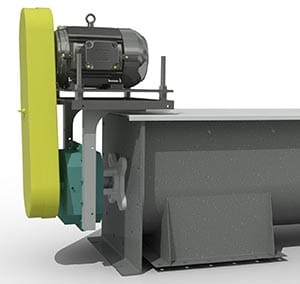

KWS Screw Conveyor

Client Needs: Replace a 304 stainless steel conveyor that was failing periodically and causing delays in production.

Products Used: A larger diameter, heavy-wall carbon steel screw conveyer.

Result: Delays at this point of production removed. Reliable around the clock functionality.

Capacity: 3379 Cubic Feet Per Hour

Duty: Continuous