Client Needs: Keep track of the total amount of material moving through a line for inventory tracking purposed

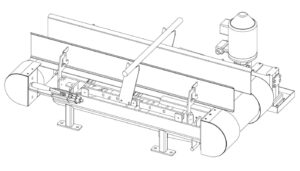

Proposed Solution: To maintain output speed, the product weighed while in transit from one position on the line to another with accuracy

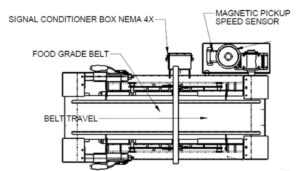

Products Used: Tecweigh Weigh Belt

Result: Accurate accounting of product moved and processed

Capacity: 21000 lbs. per hour

Duty: Continuous