Specialized Analysis Engineering (SAE) is an engineering firm dedicated to designing and automation processes for various industries such as automobile, oil and gas, aerospace, food processing, and steel making.

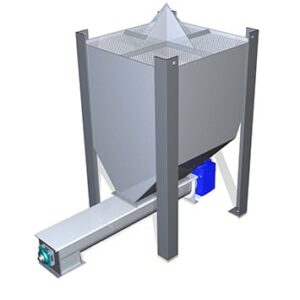

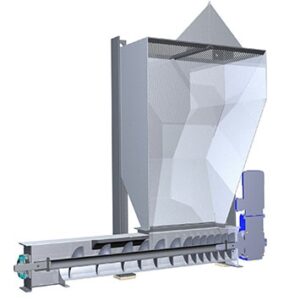

Specialized Analysis Engineering had a very specific application for storing and metering silica sand at a local Nucor Steel facility in Plymouth, UT. Bulk bags of silica sand are brought into the facility and needed to be metered at a precise rate in the process. Bulk bags are lowered over the hopper, razor-sharp bulk bag breaker bars contact the bottom of the bulk bags, cut open the bags, and discharge sand into the hoppers. The sand is then discharged into the screw conveyor where the correct amount is moved down the line.

Annik and KWS worked closely with Specialized Analysis Engineering and Nucor to design the equipment to integrate into Nucor Steel's existing production line.

Client Needs: Unload bulk bags of sand and meter out a very precise amount through the conveyor

Products Used: KWS bulk bag unloading hoppers with integrated screw feeders

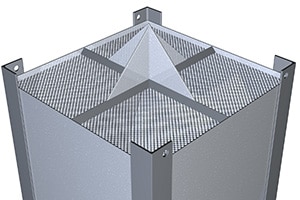

Special Features: Wire mesh safety screens welded to the inlet areas of the hoppers, preventing possible exposure to personnel

Annik Advantages: Collaboration and value engineering

Capacity: 540 Feet Per Hour

Duty: Intermittent